Rock concrete splitting machine

Release Time:

Oct 16,2023

Rock concrete splitter is a heavy-duty mechanical equipment used to remove and separate rock and concrete. It uses powerful power and advanced technology to play an important role in construction and infrastructure demolition, quarry plants and excavation. This article will describe the features and advantages of this product from different perspectives.

Rock concrete splitter is a heavy-duty mechanical equipment used to remove and separate rock and concrete. It uses powerful power and advanced technology to play an important role in construction and infrastructure demolition, quarry plants and excavation. This article will describe the features and advantages of this product from different perspectives.

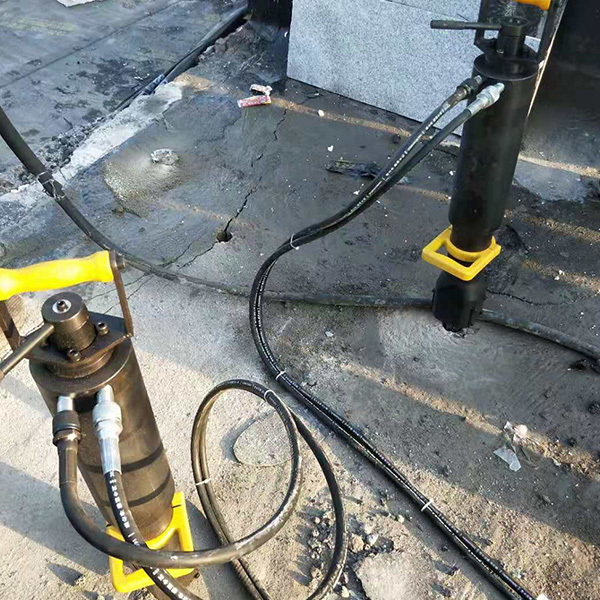

First of all, the main working principle of the rock concrete splitter is to use high-pressure oil to drive the piston to divide the rock or concrete object into smaller parts. Its structure is solid and can withstand the application of high pressure, ensuring the stability and efficiency of the cutting process. Moreover, the machine has a modular design and different working heads can be replaced as needed to adapt to different splitting requirements.

Secondly, the rock concrete splitting machine has powerful splitting capabilities. Whether it is solid granite, limestone or a solid concrete structure, it can be cut into blocks of the required size. This splitting method is very precise and will not cause excessive damage to the surrounding environment and structures, greatly improving the safety of the demolition and quarrying process.

In addition, the rock concrete splitter is efficient and flexible during the construction process. Its operation is simple and convenient, requiring only a skilled operator to complete the splitting work. Compared with traditional blasting methods, rock concrete splitting machines do not require the use of explosives, so they do not produce vibration, noise and air pollution, and are more environmentally friendly. At the same time, it can be used in small spaces and places with limited height, and is very adaptable.

Rock concrete splitting machines can also save time and labor costs. It splits quickly and only takes a few minutes or even seconds to complete a cutting action. At the same time, its splitting effect is more precise and even, reducing the workload of post-production repair and processing. For large-scale engineering projects, this can not only improve construction efficiency but also reduce costs, and has extremely high economic value in addition.

To sum up, the rock concrete splitter, as an efficient, environmentally friendly, safe and economical construction machinery and equipment, plays an important role in the fields of demolition and quarrying. Its powerful splitting ability, high efficiency and flexibility, as well as the advantages of saving time and labor costs, have attracted widespread attention and application in the market. Therefore, the rock concrete splitter is undoubtedly one of the indispensable and important tools in the construction industry.

What Else Might You Learn?