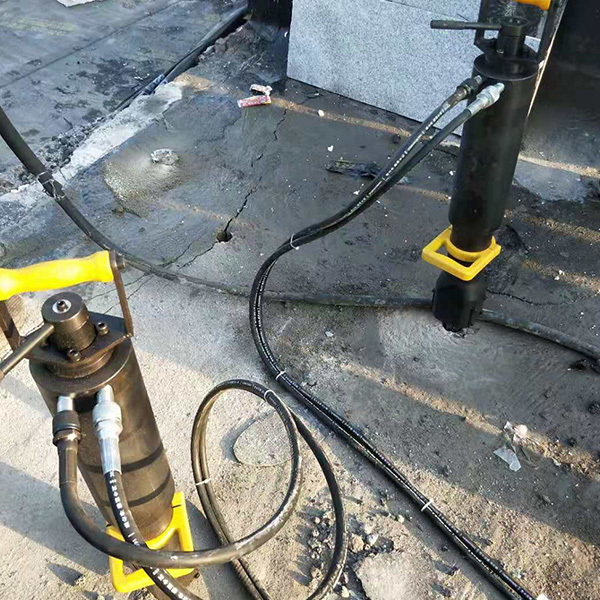

Failure of down-the-hole drill during excavation and modification

Release Time:

Oct 16,2023

The excavation and modification drilling rig is unable to dig. Inability to dig is one of the typical failures of the excavation and modification drilling rig. Inability to dig can be divided into two situations: one is inability to dig, the engine does not hold the vehicle, and the load feels very light; the other is inability to dig, when the boom or stick is extended to the bottom, the engine severely holds the vehicle or even stalls.

The excavation and modification drilling rig is unable to dig. Inability to dig is one of the typical failures of the excavation and modification drilling rig. Inability to dig can be divided into two situations: one is inability to dig, the engine does not hold the vehicle, and the load feels very light; the other is inability to dig, when the boom or stick is extended to the bottom, the engine severely holds the vehicle or even stalls.

1. Digging is weak but the engine does not hold the car:

The size of the digging force is determined by the output pressure of the main pump, and whether the engine is held back depends on the relationship between the torque absorbed by the oil pump and the output torque of the engine. Holding the car without turning means that the oil pump absorbs less torque and the engine load is light. If there is no obvious abnormality in the working speed of the excavation and modification drilling rig, the maximum output pressure of the main pump, that is, the system overflow pressure, should be checked. If the measured value of the overflow pressure is lower than the specified value, it indicates that the overload relief valve setting value of the hydraulic circuit of the mechanism is incorrect, resulting in premature overflow of the mechanism and inability to work. You can adjust the machine by turning the adjustment screw.

2. Excavation is weak and the engine is holding up:

If the engine is held back, it means that the absorbed torque of the oil pump is greater than the engine output torque, causing the engine to be overloaded. For this kind of failure, you should first check whether the engine speed sensing system is normal. The inspection method is similar to the engine inspection method mentioned above. After the above detailed inspection and troubleshooting, the engine speed sensing system returns to normal functions, the engine holding phenomenon disappears, and the digging force returns to normal.

Key words:

What Else Might You Learn?