Hydraulic mountain splitter, rock splitter, electric rock splitter, construction site

Release Time:

Oct 16,2023

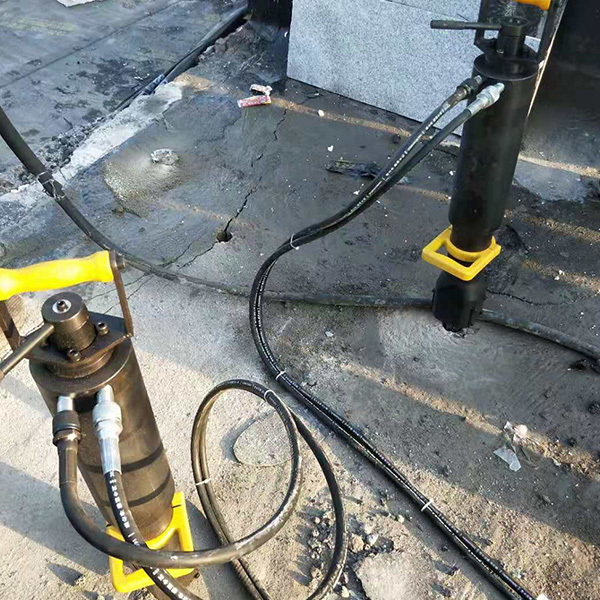

The large hydraulic rock crusher splitter can assemble and disassemble two working modules at one time. If the breaker needs to be replaced, it can also be done at the same time. The splitting machine adopts an external design and is easy to operate.

The large hydraulic rock crusher splitter can assemble and disassemble two working modules at one time. If the breaker needs to be replaced, it can also be done at the same time. The splitting machine adopts an external design and is easy to operate.

Split rock can be used for splitting a variety of rocks. The split rock is introduced into the hydraulic station of the splitter through an oil pipe, and then output to the wedge between the two split blocks of the split rock through the oil pipe through the control valve in the hydraulic station.

Scope of application of hydraulic splitting machines: The rock mining process is mainly divided into five major steps: mining, mining, crushing, spalling and demolition. Among them, the advancement of mining technology is the core driving force for the widespread use of mountaineering machines.

What are the rock mining equipment:

①Mountain cutting machines include: excavators, scrapers, breakers, etc.

②The main mining methods include: hydraulic rock breaking splitting machine, hydraulic splitting rod, etc.

③Which equipment should be used during mining? Hydraulic splitting machines are generally used for rock mining; mountain splitting machines and rock splitting machines only need to be inserted into one hole to complete the entire operation.

The working principle of the crushing and splitting machine: The rock has high strength and moderate hardness: the hardness of hard rock is greater than HV, and the hardness of soft rock is greater than HV. Therefore, when mining hard rock, there is no need to consider the problems of equipment and workers themselves.

Several methods are relatively simple to use in rock mining: drilling holes, placing holes, placing holes, drilling holes, placing holes (the drilling depth can be selected according to the rock material) and drilling holes (requiring the location and distance of the holes) Need to be selected according to the rock material); During the drilling process, generally 3-4 drilling rods need to be connected, and moisture-proof clothing and insulating shoes need to be worn when drilling; During the drilling process, the drilling rods are put into the hole; After the hole is completed, place the rock mass on the rock, place a rock rod into the hole, adjust the hole position, and then place a rock rod into the rock mass.

Key words:

What Else Might You Learn?