How does the splitter work?

Release Time:

Oct 16,2023

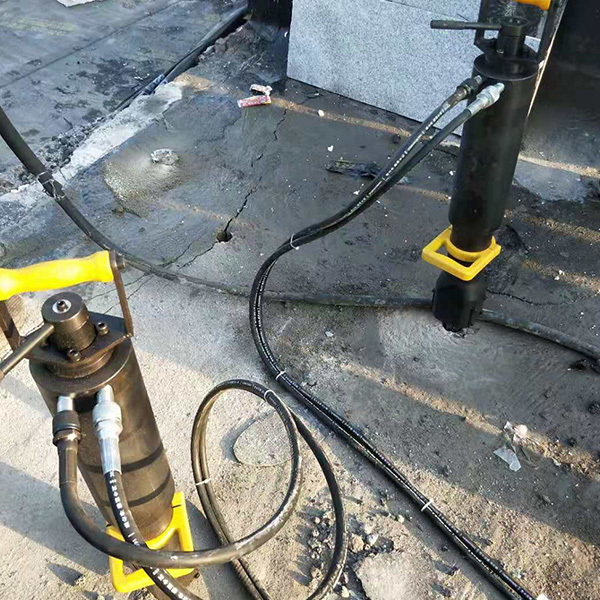

Using high-pressure oil as the energy source, the ultra-high-pressure oil output from the pump station drives the oil cylinder to generate a huge driving force, causing the splitter to push the wedge to expand the split blocks to both sides, reaching several thousand tons. After mechanical amplification, it can be easily done within ten seconds. The earth splits a thousand-ton boulder from within the object and causes the object to split in predetermined directions. This separates the hard and huge ore from the mountain.

Using high-pressure oil as the energy source, the ultra-high-pressure oil output from the pump station drives the oil cylinder to generate a huge driving force, causing the splitter to push the wedge to expand the split blocks to both sides, reaching several thousand tons. After mechanical amplification, it can be easily done within ten seconds. The earth splits a thousand-ton boulder from within the object and causes the object to split in predetermined directions. This separates the hard and huge ore from the mountain.

Key words:

What Else Might You Learn?